Home / Our 5 Step Process

Our Process

Our 5 Step Process

A professional floor coating system requires precision, industry-grade tools, and a carefully structured workflow. Our process ensures long-lasting durability, flawless adhesion, and a stunning finish that transforms any residential or commercial space.

Surface Prep

Proper preparation is the foundation of every successful coating system.

At this stage, we:

- Diamond grind concrete with our industry standard grinders

- Remove any dirt, grease, oils, or contaminants from concrete

- Grind away old coatings, paints, or sealers

- Vacuum dust and loose materials

- Ensure the floor is completely dry and ready for mechanical profiling

This step guarantees a clean surface so the coating bonds strongly and uniformly.

Diamond Grinding

We use heavy-duty, industrial diamond grinders to mechanically profile the concrete.

This process:

- Opens the pores of the concrete

- Creates the ideal surface texture for coating adhesion

- Removes weak layers, laitance, and imperfections

- Levels uneven areas of the slab

Diamond grinding is crucial because it replaces the need for acid etching and ensures the coating fuses directly with the concrete for maximum longevity.

Crack Repair

Floors often have cracks, pits, or spalling that must be repaired before applying coatings.

We carefully:

- Fill cracks with our professional crack fillers

- Fix pits, divots, and surface breaks

This creates a structurally solid base so the final coating looks flawless and performs reliably.

Epoxy Basecoat Application

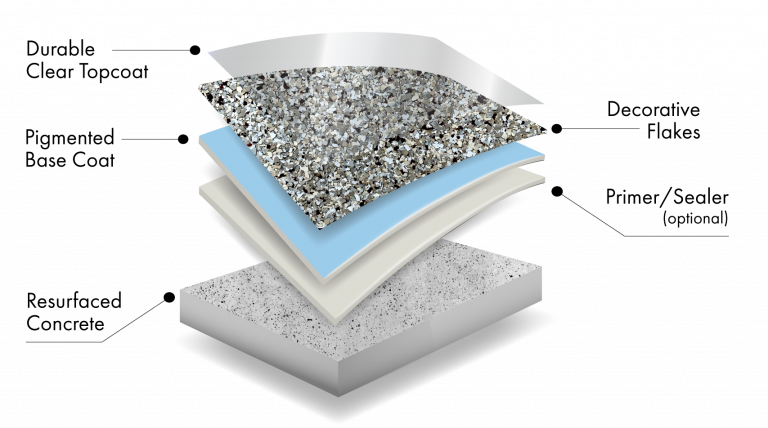

Once the surface is repaired and properly profiled, we apply a premium 100% solids moisture vapor barrier basecoat.

This layer:

- Acts as the foundation of the entire system

- Provides strong adhesion to the concrete

- Adds durability and chemical resistance

- Ensures flakes bond securely during broadcast

The basecoat is rolled on evenly to create a uniform, high-build layer.

Full Flake Broadcast

While the epoxy basecoat is still wet, we broadcast decorative flakes across the entire surface until full coverage is achieved.

This step:

- Adds color, texture, and aesthetic depth

- Provides slip resistance for safer flooring

- Increases thickness and durability

- Hides imperfections for a consistent appearance

We use high-quality vinyl flakes available in multiple blends, allowing customers to choose the perfect style.

Polyaspartic Clear Topcoat

The final step is applying a professional-grade polyaspartic clear topcoat.

This protective layer:

- Seals the flakes and locks the system in place

- Provides exceptional UV, chemical, and abrasion resistance

- Prevents yellowing or fading over time

- Delivers a smooth, glossy, and easy-to-clean finish

- Ensures long-term durability in both residential and commercial environments

Polyaspartic topcoats cure quickly, allowing the floor to return to service faster.